Like sands through the hourglass – but not quite

Researchers design new granular materials that flow but can still be compressed

1 April 2024

One can find them all along the coast of Japan: tetrapods, enormous four-legged blocks of concrete that prevent erosion of coastal structures. Together, these tetrapods form a granular metamaterial: a granular material like sand, but designed and made by humans. Tetrapods have their shape for a good reason. The extended legs make it very difficult for a pile of these blocks to flow. Contrary to ordinary boulders, they stay in their place, and as a result they do what they were intended to do: prevent the coastline from changing.

Easy compression, easy flow

The example of tetrapods shows that it is relatively easy to make a granular system which is almost incompressible and flows far worse than sand. On the other end of the spectrum, it has turned out to be very difficult to create a material which is easy to compress and flows better than sand. Due to the work of the researchers from Amsterdam and Santiago, published in the Proceedings of the National Academy of Sciences this week, this situation has now changed – opening up very interesting opportunities.

Daan Haver, first author of the publication, explains: “In the field of metamaterials, we construct the geometry of a material in such a way that the material has a desired response. For example, we normally expect an elastic band to become thinner when we stretch it. In previous work, researchers have shown ways to make materials which become thinner not when stretched but when compressed, purely based on the geometry of the material. This example shows that it is possible to tune the properties of your material. We were wondering if we could use this idea to also tune granular materials.”

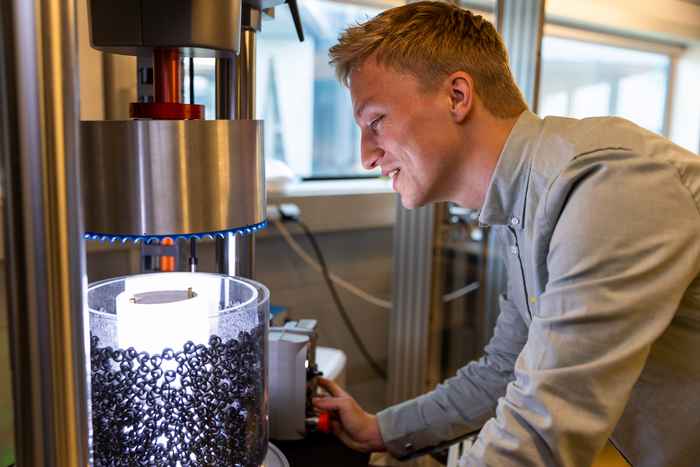

In the lab, the researchers made grains that shrink radially when there is an external pressure. That means that when a packing of these grains is compressed, the amount of free space between the grains remains roughly the same, and as a result the flowing behaviour of the grains remains similar to that of a liquid. Haver: “The forces inside the medium remain low. Therefore, the packing is not only very compressible but can also flow better. We put the grains in a funnel. Normally, grains will form an obstructing arc. However, when the grains shrink with respect to the opening size, the grains will eventually flow. It was always thought that granular materials would be difficult to compress and that changes to grains would deteriorate flowing properties. With our new grains, we opened up a direction where we can create totally different packings that are easy to compress and which still flow easily.”

Shock dampening

The new results could have great potential in shock dampening. The researchers showed that a metal disk, when dropped into a packing of the new grains, slows down over a long period of time and barely bounces back. The energy of the disk’s motion is thus transferred more consistently and homogeneously to the packing. Haver: “Imagine, instead of a metal disk, someone falling in a speed skating race. The impact on the skater when hitting the wall would be small if the new grains are used inside the cushion. As a big bonus, the person would not be bounced back on the track, making the situation safer for everyone involved.”

Publication

Elasticity and rheology of auxetic granular metamaterials, Daan Haver, Daniel Acuña, Shahram Janbaz, Edan Lerner, Gustavo Düring and Corentin Coulais, PNAS 2024, 121 (14) e2317915121.

Further supplementary video material can be found in this YouTube playlist.