Closing the loop for mixed cotton/polyester waste textiles

Consortium aims to develop upcycling route to virgin monomer building blocks

29 June 2022

The MIWATEX consortium (an acronym for Mixed cotton/polyester WAste TEXtiles) includes partners from chemical industry and businesses across the textiles value chain. UvA Social Psychology researchers Prof. Frenk van Harreveld and Dr Cameron Brick will contribute with their expertise in consumer behaviour and communication. The MIWATEX consortium will receive €985.000 funding by the Dutch Research Council NWO from the call 'Circularity' of the Knowledge and Innovation Convenant. Including the co-funding of the participating companies the total budget is €1.3 million.

Recycling cotton/polyester blends

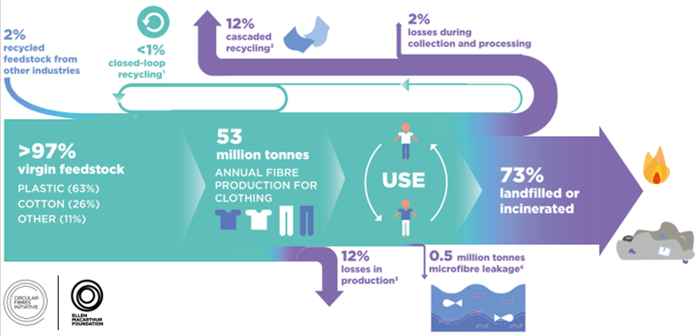

Textile recycling requires a relatively pure waste stream, but most textiles are made up of blends of two or more materials. As a result, a huge amount of textile waste ends up in landfills or incinerators each year: 110 million tonnes, or 13 kg per person globally. Clothing and other textiles containing a mix of cotton and polyester (PET) make up the largest part of this huge volume, but currently there are no viable techno-economic options for recycling cotton/polyester blends.

The MIWATEX consortium hopes to change that. The starting point is a recently developed approach for recycling cotton to valuable monomers using the so-called DAWN biorefinery technology developed by the Amsterdam-based chemical technology company Avantium. According to Gruter, who is CTO of Avantium, proof-of-principle was obtained for hydrolyzing cotton (cellulose) to valuable molecular building blocks, even when mixed with polyester. This opens a recycling route for both the cotton and the polyester from the mixed textile blends. The MIWATEX consortium aims to establish a recycling value chain based on this route.

Focus on technology as well as consumers

Gruter’s research group Industrial Sustainable Chemistry will collaborate with Avantium and CuRe technology on the enabling technology for making mixed cotton/polyester waste recycling a reality. As the main technology partner, Avantium will host and guide two MIWATEX PhD students in their Amsterdam labs. CuRe is a partner for plugging-in the PET chemical recycling into their technology. Since this company already has an extensive network in the textile industry, through CuRe many textile brands are connected to this project. In addition, with the companies Groenendijk Bedrijfskleding, Wieland Textiles, and the Modint trade association for manufacturers and suppliers in the fashion and textile industry, the consortium has relevant partners across the textiles value chain, including sorting and recycling.

Since the success of the circularity value chain will depend heavily on consumer attitudes and behaviour, the consortium will see frequent interactions between all partners and Social Psychology researchers Prof. Frenk van Harreveld and Dr Cameron Brick. This builds upon the current collaboration between the Gruter research group and the UvA Social Psychology researchers, which started 4 years ago with PhD student Maria Zwicker in a successful collaboration around consumer attitudes towards more sustainable (bio-based) plastics. Within MIWATEX, a postdoc will be appointed to work within the Amsterdam Behavioral Insights Lab, coordinated by Brick, and will be affiliated with the Centre for Sustainable Development Studies at UvA. In addition, relevant input for consumer studies will be collected from all consortium members.

See also

- Green light for urgent research on circular plastics and biobased resources (NWO)

- Gert-Jan Gruter: "I want to develop new materials that meet the demands of today"

- Research group Industrial Sustainable Chemistry

- Social Psychology research programme

- Amsterdam Behavioral Insights Lab

- Centre for Sustainable Development Studies