The TC specialises in the development, modification, maintenance and production of unique, high-quality technological equipment and configurations intended for scientific research in the exact sciences. You can rely on our support in relation to electronics, software, mechanics and glass instrumentation, and we can advise on equipment purchases.

Technology Centre

Unique research, unique equipment

-

Quick Service

The Quick Service allows staff at the Faculty of Science to have small jobs completed quickly. An electronics engineer, instrument maker, glass instrument maker and computer specialist all form part of the Fast Service team and aim to offer a same-day service. It is also possible for Faculty of Science staff members to tackle simple jobs in the workshops themselves, with the expert guidance and support of the manager of the Fast Service workshop.

-

Electronics

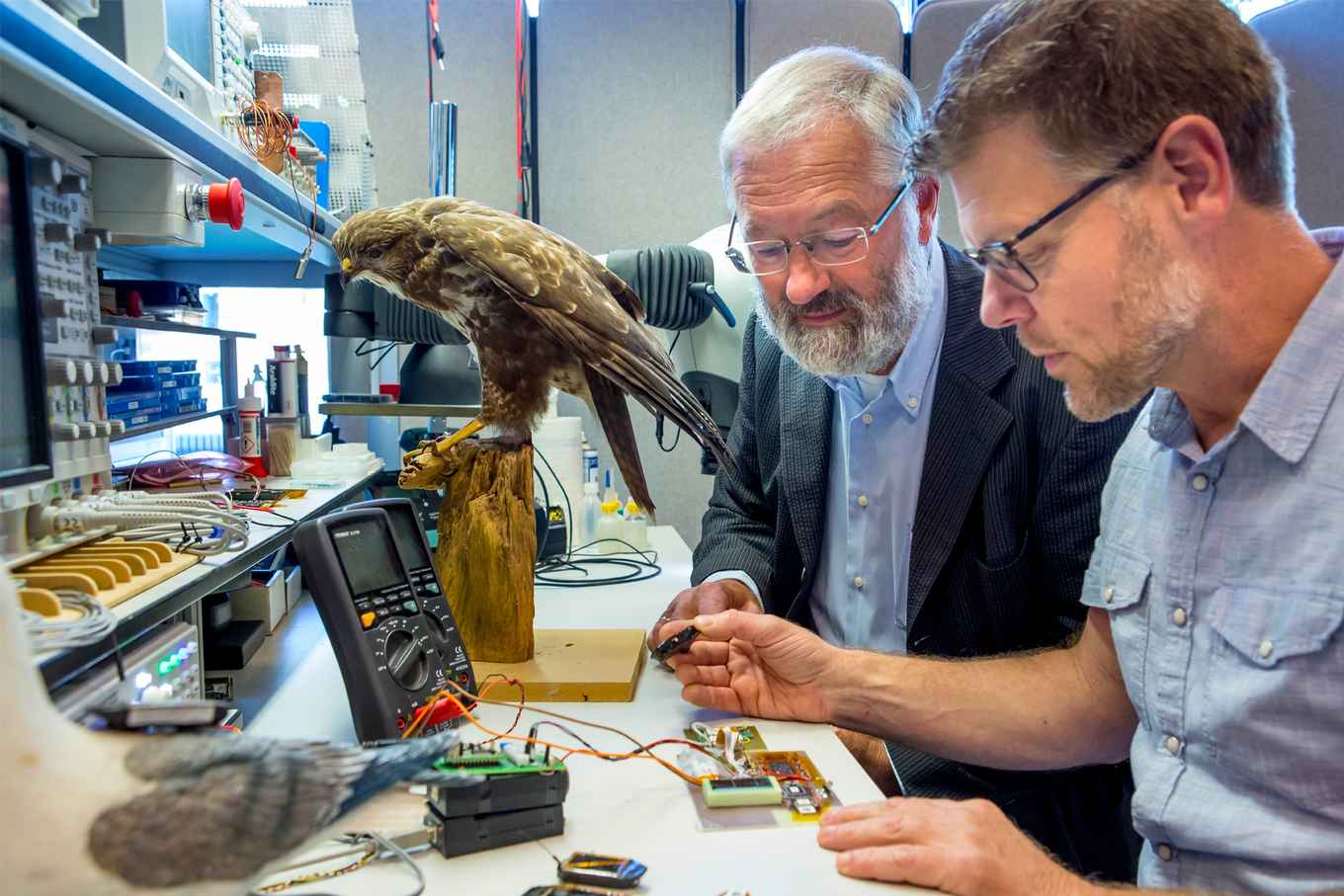

Electronics specialists at the TC help the experimental groups to design, build, repair and maintain electronic equipment. They specialise in the development of advanced measurement and control systems. One new development is extreme miniaturisation, which is vital for many biological experiments. Advanced CAD software is used to develop the hardware required. The TC has extensive experience with flexprint material for ultralight electronic circuits, but also with electronics for high-voltage, data transmission and high-frequency techniques. In collaboration with the TC’s software specialists, many circuits are enhanced with programmable logic, such as FPGAs or microcontroller systems.

Edwin Baaij (Technology Centre) and Willem Bouten (biologist). -

Software

The activities of software specialists are complementary to the work of electronics engineers in the field of programmable logic, data acquisition and embedded software. Besides embedded software on off-the-shelf Linux boards, PC software is also regularly written in various programming languages, which scientific groups can then choose to expand. For scientific data acquisition and controlling experiments you can use a Python or C#. To start your software programming you can get help and advice on a software design. To speed up the process you can also get help with the actual programming.

TC expertise is available in the following areas:

- Software written in C/C++, Python (PyQt), C# and Matlab

- Web applications with JavaScript, css and databases

- Linux operating systems and device drivers, including real-time

- Data analysis and presentation, including real-time

- Embedded software in various microcontrollers

- Software for programmable logic in VHDL and Verilog

- Advice on server applications and version management

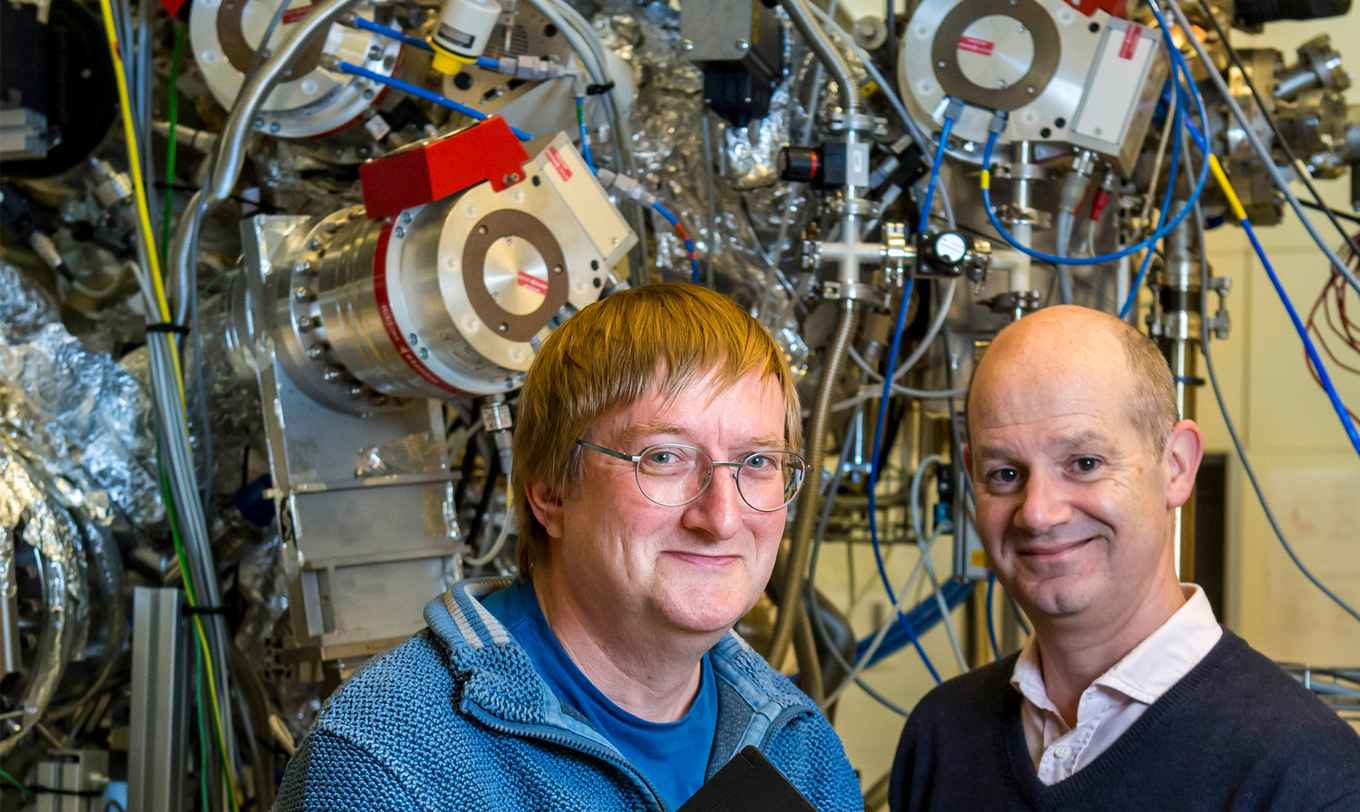

Gerrit Hardeman (Technology Centre) and Mark Golden (physicist). -

Mechanical Engineering

The mechanical workshops are used to build new equipment, make modifications and carry out repairs. The instrument maker has a wide range of equipment, including conventional and computer-controlled machine tools. Armed with a five-axis milling machine, complex parts can be produced with a precision of just several micrometres. TIG and Plasma welding equipment is used to weld metals as thin as 0.2 mm. The (3D) measuring machine makes it possible to identify dimensional and form deviations of 2 microns when carrying out final checks.

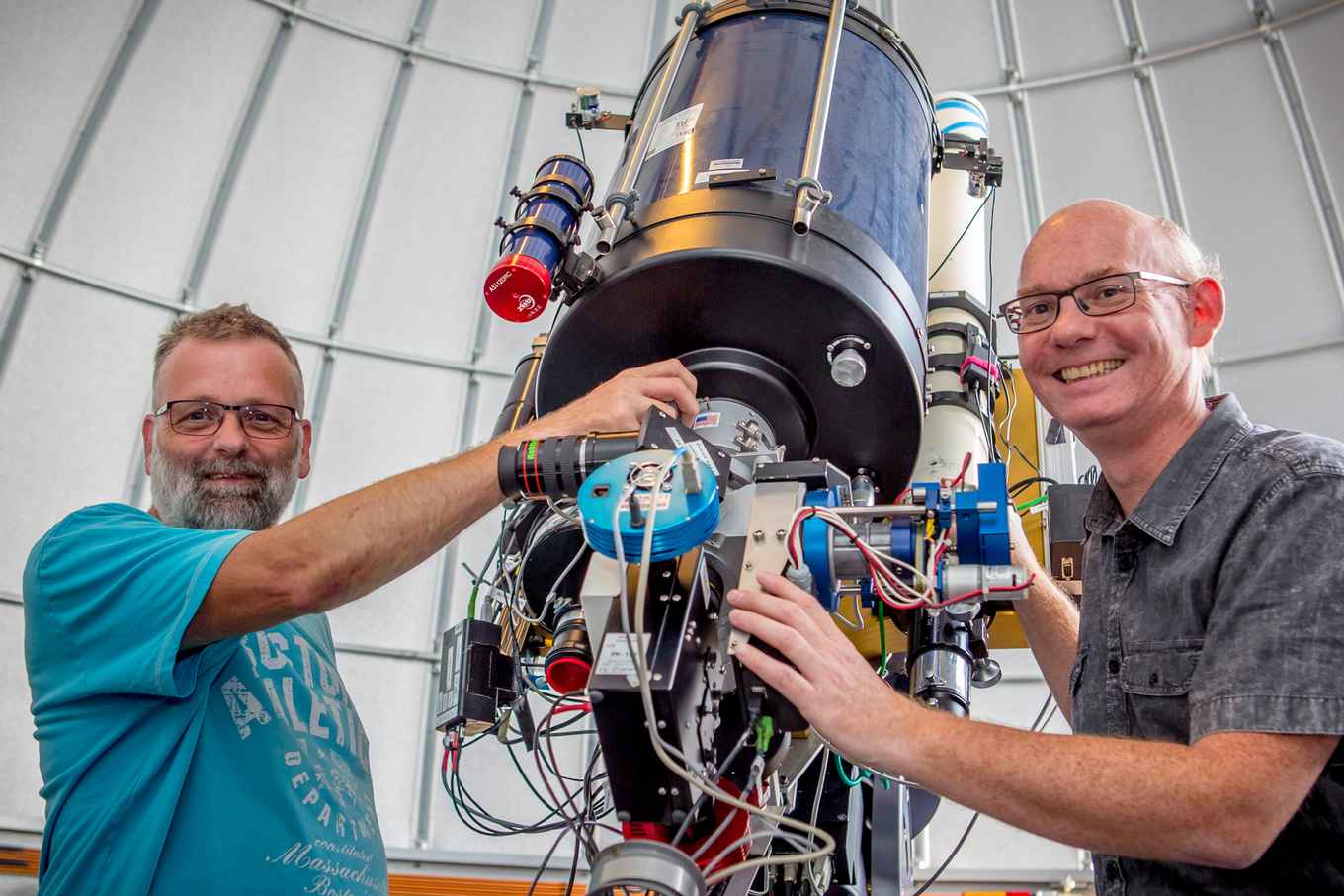

Mattijs Bakker (Technology Centre) with Rudy Wijnands (astronomer). -

Workshop

Through a combination of skilled craftsmanship and precision equipment, technicians and engineers work with scientists to create exactly what's needed, whether it's measured in microns or meters.

Aided by three-dimensional CAD and simulation software, experienced designers are able to deliver the very best solution for virtually every mechanical design problem. Besides mechanical properties, it is possible to predict thermal, magnetic or other physical behaviour of a design too. This could lead to a recommendation, a physical report (containing specifications or safety aspects, for example) or a complete folder of working drawings, including 3D visualisations.

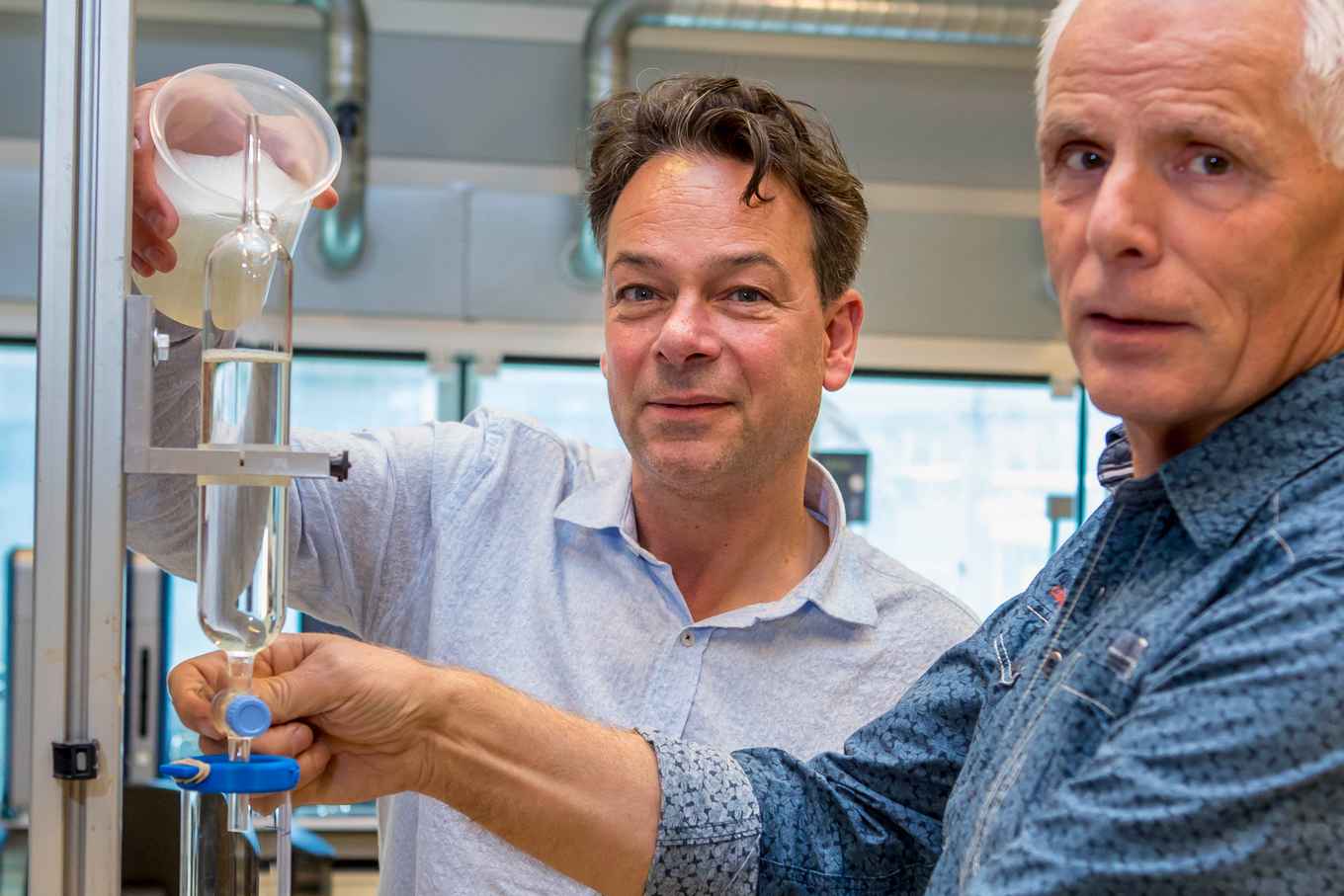

TC staff member Tjeerd Weijers with former researcher Martin Brandenbourger -

Glass Instrumentation

Glass has special properties. For example, it is transparent, chemically inert, an electrical insulator, gas-tight, resistant to temperature fluctuations, a radiation filter and non magnetic. Depending on the specific requirements and wishes, it can be the best or sometimes the only option.

The Glass Instrument Workshop develops and produces custom-made glass instruments, optical components and configurations, and delivers solutions for glass engineering issues. It also modifies existing configurations and instruments and carries out repairs.

The newest innovation is 3D-printing of quartz glass and 2D-machining of complex contours in glass with a waterjet and laser welding of embedding metals like platina, gold and silver.

The Glass Instrument Workshop uses the following techniques:

- Hot working of borosilicate and quartz glass

- Cold working (cylindrical grinding, sawing, drilling and surface grinding) of any type of glass and technical ceramics (Al2O3), makor and silicon carbide, etc. using diamond tools

- Cylindrical griding of screw threads and spiral grooves for quartz and ceramic oven tubes

- Stretching capillaries to a thickness of 0.08 mm

- Vacuum soldering for optical glass without deformation

- Connection techniques like (UV-)adhesive and glass-metal constructions

- Using melting to embed samples in quartz or borosilicate glass with the addition of a protective gas

We can also assist in obtaining non-standard optical components such as prisms, mirrors and lenses. And we are experienced in giving advice on the various applications of coatings (AR, high reflection, filters).

Because of its transparency, glass is also extremely suitable as a demonstration aid and as a model. Due to its formability and graceful properties, glass is also a beautiful material for awards and parting gifts.

Gertjan Bon (Technology Centre) - Guided tours of the Technology Centre

-

Contact

Do you want to know more about our services? Please do not hesitate to contact Alix Wattjes, head of the Technology Centre.

Or contact one of our specialised staff members

Our address

Science Park 904

1098 XH AMSTERDAM

Tel: 020 - 525 5009 -

Work at TC?

Interested in a position at TC? You will find all our open vacancies at vacatures.uva.nl.

If there are no vacancies, you can send an initiative application to or contact Alix Wattjes, Head of Technology Center.